CNC (Computerized Numerical Control) Machining is an subtractive manufacturing process using the high-speed rotating cutting tool to precisely remove the unwanted material from a solid workpiece to ... More

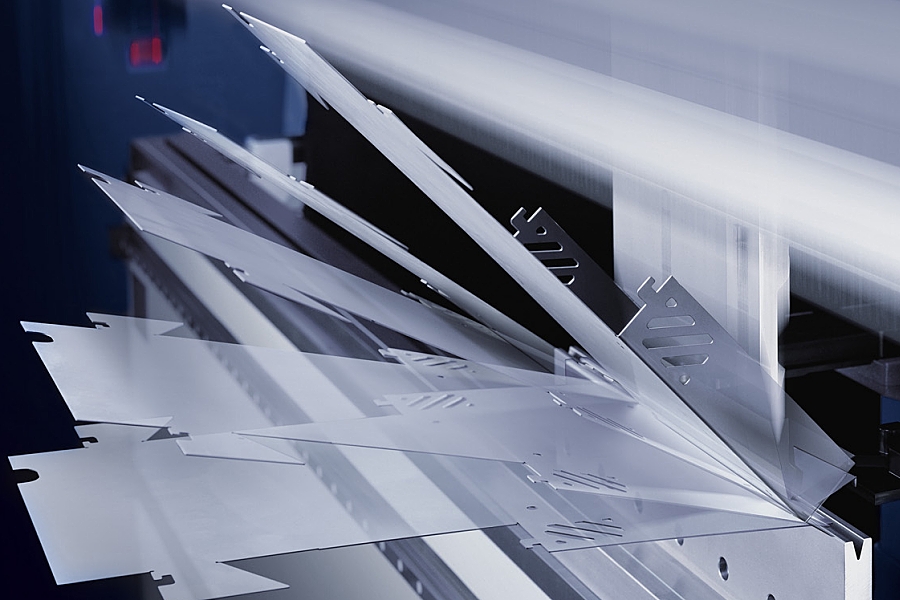

Sheet Metal Fabrication involves cutting, punching, bending, stamping, stretching and welding the metal sheets into intended structures and shapes. The metal sheet thickness ranges from as thin as 0.2 mm ... More

Plastic Injection Molding (PIM) injects molten plastics into mold cavity at high pressure and temperature to mold the parts efficiently. The durable mold made of rigid ferrous metal delivers hundreds of thousands ... More

Reaction Injection Molding (RIM) is a Cold and Low-Pressure casting process that specializes in low volume manufacturing large and complex-geometry parts quickly and economically. The most commonly ... More